Laser marking on consumer packaged goods (CPG): What makes Videojet SmartFocus™ technology the smart choice?

Videojet Knowledge Hub Team

laser, CPG, Videojet SmartFocus™ technology

Laser marking has become a key solution for coding on consumer packaged goods (CPG), but traditional systems often require manual adjustments for changeovers that slow production. Videojet SmartFocus™ technology revolutionizes this process by enabling automatic, high-speed focal adjustments for consistent, high-quality codes across diverse packaging materials.

What is the Videojet SmartFocus™ technology?

With Videojet SmartFocus™ technology, the laser automatically adjusts the focus distance to a distance predetermined during setup, accommodating different product sizes and substrates quickly and accurately. This time-saving feature helps ensure that production can proceed swiftly and seamlessly without compromising on quality.

“I just set the appropriate height once on the display, and then it adjusts automatically and always fits. The most important thing is the legibility of the text. It’s a definite improvement because with Smart Focus, it’s like a recipe; it’s independent of the bottle size, and the laser more or less takes over the work.”

What is laser marking and how does focal distance affect code quality?

As laser technology has evolved over the last 30 years, laser marking has become the main alternative to the inkjet printing of codes and other information on primary and secondary packaging, as well as on metal parts.

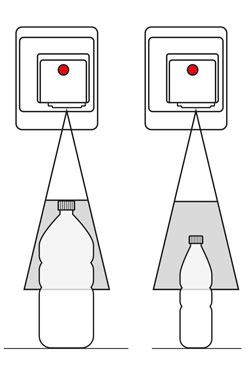

- A laser beam is diverted by two motor-driven, computer-controlled mirrors and then focused on the product surface using a focal/scan lens.

- Similar to a magnifying glass, the product surface must be positioned at a specific focal distance from the laser marking system to achieve sharp, high-contrast codes.

- If the package size or distance from the marking system changes, the focal distance must be adjusted to keep the product in focus.

- This adjustment is typically done by mechanically or manually moving the laser marking system closer or farther away.

How does 3D laser technology work for parts marking?

Featuring additional capabilities over standard laser systems, 3D laser marking was developed to code on uneven surfaces, such as the parts of a product that are not in the usual focal distance to the marking system. The 3D systems can vary the focal distance within a certain range without moving the laser system.

What are the challenges with 3D marking systems?

The primary application for the first generation of 3D marking systems was in coding on metal parts with a given geometry. These laser systems adjust the focal distance correctly for each spot of the product surface. This is done by loading 3D data (e.g., STEP files) into the system. With 3D marking, the products are not moving while being coded. As a result, production speed is quite limited when achieving high-quality engraving and marking, and 3D lasers’ usefulness in CPG marking is minimal.

How does Videojet SmartFocus™ technology improve CPG marking?

Videojet has taken laser marking technology a step further and optimized it for CPG applications. Unlike existing 3D marking systems, Videojet SmartFocus™ technology is best suited to code on products moving and at the highest production line speeds, in addition to stationary products. Without sacrificing code quality, Videojet SmartFocus™ technology can deliver consistent codes on more than 100,000 products per hour, depending on factors like the code complexity, substrate, and line configuration. Product changeovers become as quick and easy as selecting a different marking job.

“On the HMI, you make the initial adjustment. Once you’ve made that adjustment, it’s ready. You just go there, choose it, and you’ll have this time-saving and cost-saving benefit in the setup. It has good efficiency.”

Comparison: 3D laser marking vs. Videojet SmartFocus™ technology

| Feature | 3D laser marking | Videojet SmartFocus™ technology |

|---|---|---|

| Best suited for | Marking on non-moving products | High-speed CPG marking on moving and non-moving products |

| Target surfaces | 3D surfaces, e.g., tooled metal parts | CPG product shapes such as film and foil packages, cardboard boxes, bottles |

| Focal distance adjustment | Slow | In milliseconds for the highest throughput and production speeds |

3D laser marking and Videojet SmartFocus™ technology address different needs: 3D laser marking is ideal for complex, static parts, while SmartFocus™ technology offers flexibility and speed for dynamic CPG lines.

What are the benefits of Videojet SmartFocus™ technology?

- No manual or mechanical adjustments are required for different product sizes. The focal distance information is stored in the marking job and adjusted automatically.

- Product changeover is quick and easy. Since the focal distance information is defined during setup, operators simply select a job without making any additional adjustments or manual entries. This process can even be automated, e.g., via a PLC to select the right marking job automatically without operator intervention when changing products.

- Changing focal distance happens in milliseconds, therefore focal distance changes can happen from product to product, if required, even at highest production speeds.

- The laser system can adjust the output power of the laser beam source and control the focal distance. Doing both can reduce the risk of damage considerably because the beam is in focus and operating with constant power at any point in the marking-field. This is especially important on substrates with enhanced potential for recyclability, such as thin, single-layer packaging materials.

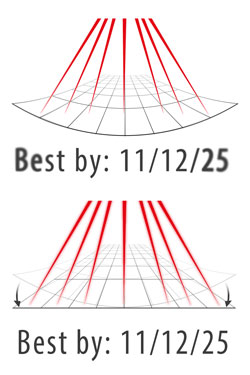

- Exceptional print quality is maintained with a uniform spot-size marking across the entire marking field and no degradation at the edge.

- While Videojet SmartFocus™ technology controls the focal distance, a side benefit is that the contrast and line width of a code can be adjusted by moving the beam either in focus or slightly out of focus. A code’s appearance can be adjusted within a certain range to be darker, bolder, lighter, or thinner.

- Using Videojet SmartFocus™ technology, 2D code quality can be optimized by adjusting contrast and spot size to deliver consistent and readable codes.

Conclusion

Videojet SmartFocus™ technology represents a significant advancement in CPG marking. With the ability to automatically adjust focal distances and maintain high-quality codes at high speeds, it can help save time, boost safety, and improve productivity. Easy product changeovers and the capacity to handle a diverse range of product shapes and materials help Videojet SmartFocus™ technology meet the evolving needs of today’s packaging operations.

See Videojet SmartFocus™ technology in action. Book a demo today!