Printing on Construction Materials

With near-constant run times, dusty environments and temperature extremes, you need a coding solution that works as hard as you do. Achieving consistent code quality over the useful lifetime of your printer is not only possible, but with robust solutions from Videojet, you can minimise your maintenance, too.

- Applications

- Line Integrations

- Documents

- Overview

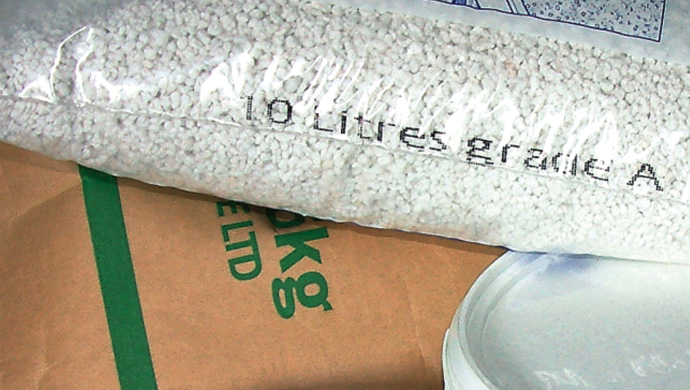

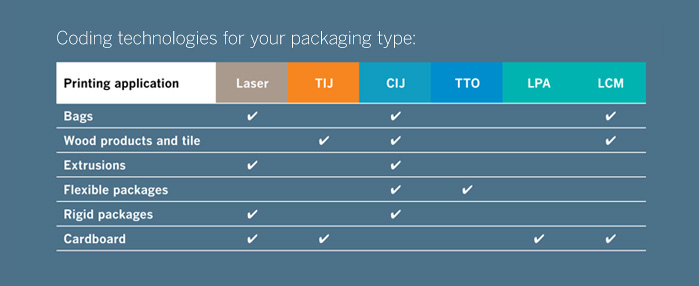

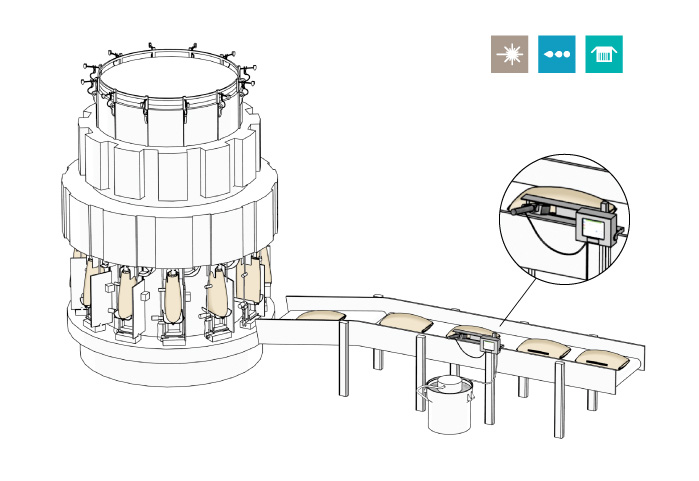

- Bags

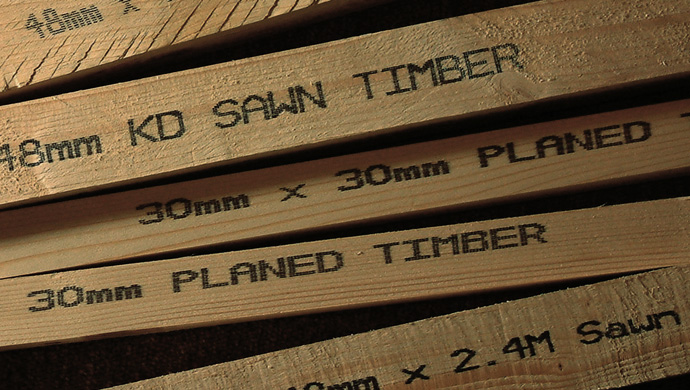

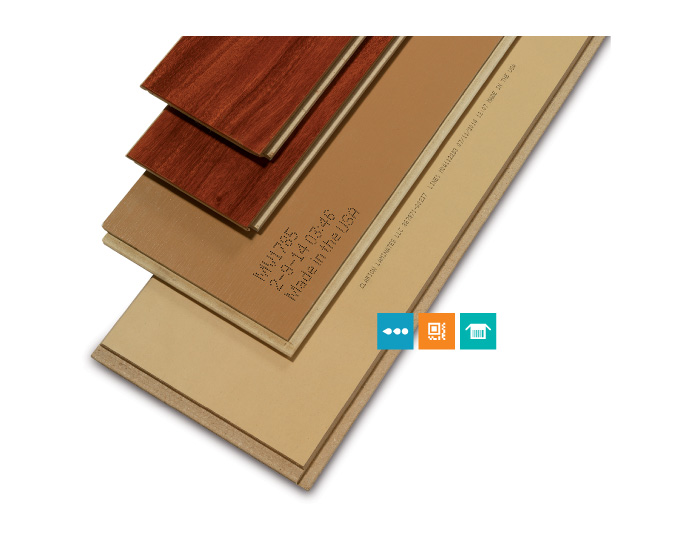

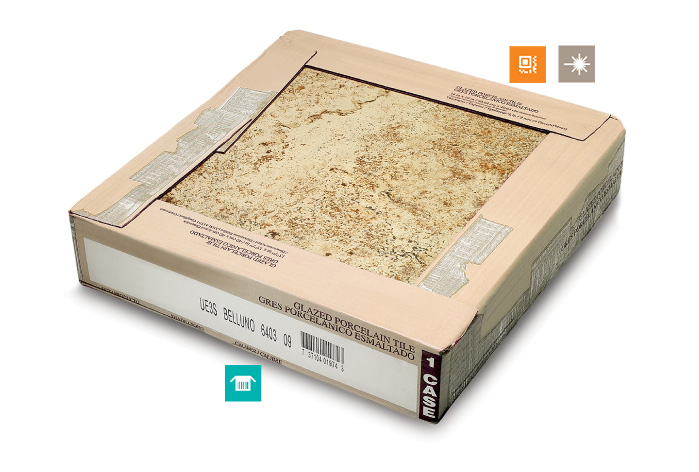

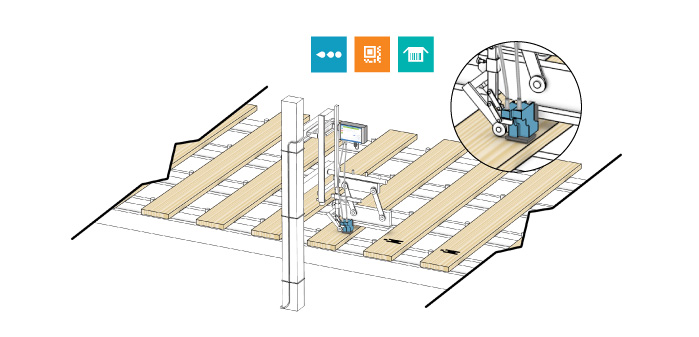

- Wood products and tile

- Extrusions

- Flexiblepackages

- Rigidpackages

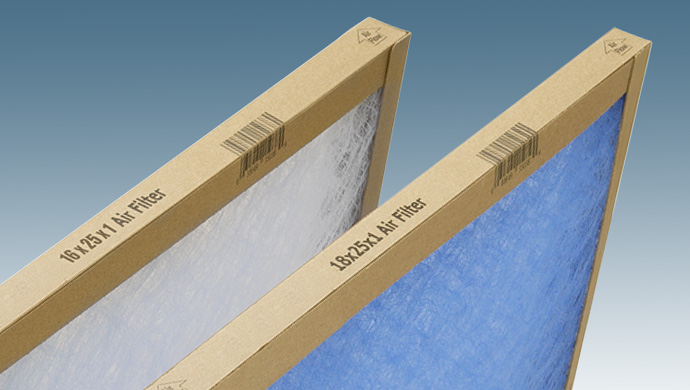

- Cardboard

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

Ink-based, non-contact printing using heat and surface tension to move ink onto a package surface. Generally used to print 2D DataMatrix and other bar codes.

Thermal Transfer Overprinting (TTO)

A digitally controlled printhead precisely melts ink from a ribbon directly onto flexible films to provide high resolution, real-time prints..

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

Ink-based, non-contact printing of multiple data types (alphanumeric, logos and bar codes) in large sizes primarily used for secondary packaging such as cases.

Label Printer Applicator (LPA)

Prints and places labels of various sizes on multiple package types.

Reliable, continuous print on paper and plastic bags

When bagging powdered materials, there can be variability with finished product placement on your conveyors. This can create distorted codes due to inconsistent throw distance from bag to bag. Equipped with the right accessories and the know-how for seamless installation on your line, Videojet experts can help you with optimal printer placement on your conveyor for clean and consistent codes.

Large Character Marking

- Large character size marking at high line speeds

- Pre-load job product codes or network your printers to minimise changeover times and entry errors

Continuous Ink Jet

- Options with CleanFlow™ technology and IP65 rating designed to minimise maintenance

- Bulk ink and make-up systems reduce operator/printer interaction

Print a variety of text, characters or logos in hot, non-stop production environments

Regardless of whether you are printing lot, date or bar codes, moisture levels, panel grades, inspector ID information, species or batch data, coding equipment selection is largely driven by the demands of your production environment. The ease of maintenance must also be taken into consideration when bulky equipment limits accessibility to your printer. Videojet offers rugged printer options that are designed for dependability, minimised maintenance, and ease of use.

Continuous Ink Jet

- Variable throw distance helps reduce printhead damage due to uneven lumber surfaces

- High resolution white and pigmented inks in black, blue, red, and yellow

Thermal Ink Jet

- Simple and cost-effective change-outs of the cartridge provides a new printhead with each replacement. This solution can be used for lumber substrates where wood slivers can damage the printhead.

- High resolution bar codes and logos

Large Character Marking

- Robust industrial printer design with IP65 cabinets available for harsh production environments

- Available micro-purge technology helps reduce required maintenance and printer damage due to operators forgetting to purge printheads

Code quality and your production environment

With the challenges of printing consistent codes in harsh environments and the cost and effort required to address operator-related coding mistakes, coding errors can quickly become a headache. Videojet offers exclusive technologies such as CleanFlow® and Dynamic Calibration™ that can help you print clean, consistent codes, even in challenging production environments. And our Code Assurance solutions can help simplify operator-to-printer interaction, and better equip operators to achieve the right code on the right product, time after time.

Continuous Ink Jet

- Pigmented inks provide high contrast on dark backgrounds, improving legibility

- Dynamic Calibration™ feature adjusts to temperature variation at the production site, helping to ensure consistent code quality

Laser Marking Systems

- Sharp, clear codes with high contrast. Highly attractive, gold-colored codes are possible on extruded PVC

- Fiber laser marking system is able to code on metal surfaces

Help reduce costs and increase packaging line flexibility

Printing product or part number information directly on the bag can help reduce pre-printed inventory holding costs, long lead times, and simplify production changeovers. By using generic film and coding variable information on demand with a Videojet Thermal Transfer Overprinting solution, you can help reduce packaging costs and increase productivity.

Thermal Transfer Overprinting

- Ideal for printing dates, logos, bar codes, other product information and graphics on generic film

- Many different ribbon colors available

- Produces high resolution codes (300 dots per inch/ 12 dots per mm) on flexible film with no solvents

- Patented clutchless ribbon drive helps minimise maintenance-related downtime and maximises ribbon efficiency

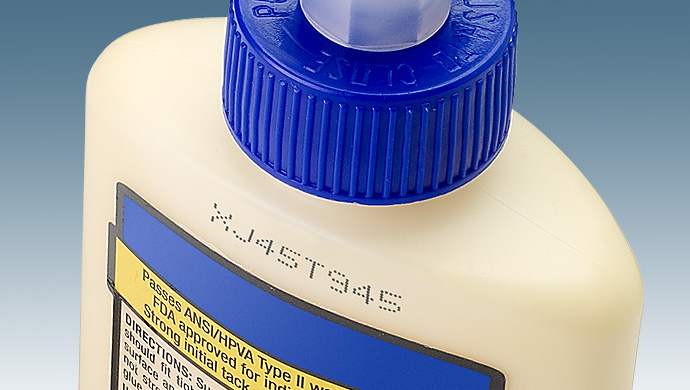

Code on almost anything

Due to their content and application constraints, many building materials packages, especially the ones designed for DIY, come in a variety of specialised containers. In the retail space, packaging design often differentiates your products and can be integral to your success. Videojet offers robust coding solutions to address the unique needs of a wide range of specialty packaging types.

Continuous Ink Jet

- Broadest portfolio in the industry at over 175 ink offerings including odourless and non-MEK inks

- Easy integration onto your line for printing on the shoulder, top or bottom of a wide variety of substrates

Laser Marking Systems

- Clean, crisp codes on plastic tubes, metal, and HDPE with UV

- Etch text, numbers, special characters and logos, even in small spaces, with curved or linear orientations

Empower your supply chain and reduce costs

Printing lot, batch and supplier-specific information on your external packaging creates a data-rich traceability point that is visible to your warehouse, wholesaler and retailer. With solutions to assist with tracking your product throughout your supply chain, Videojet offers scalable software and production-line control systems for nearly every material and production environment. Moreover, there are cost-savings opportunities with print on demand solutions for exterior packaging – helping to reduce the costs of using and maintaining pre-printed cases.

Thermal Ink

Jet

- High resolution, ink-based printing with no wear parts, minimising maintenance and related downtime

- Solution with MEK-based inks helps ensure excellent code adhesion on non-porous substrates

Laser Marking Systems

- Comprehensive portfolio of laser accessories, lenses and beam turning units for easy integration

- Especially useful for water-resistant coated boxes as it enables clear, dark printing without damage to protective coatings

Label Printer Applicator

- High quality thermal transfer coding direct to labels

- Automated application offers greater speed, accuracy, and error prevention than hand labelling

Large Character Marking

- Bar code scanner available to enter code information directly from production order into printer

- Message capacity to handle multiple jobs with easy and fast code selection, helping to minimise changeover time

- Weighing control and bag filler

- Wood products and floor tile

- Extrusion

- Vertical form, fill and seal

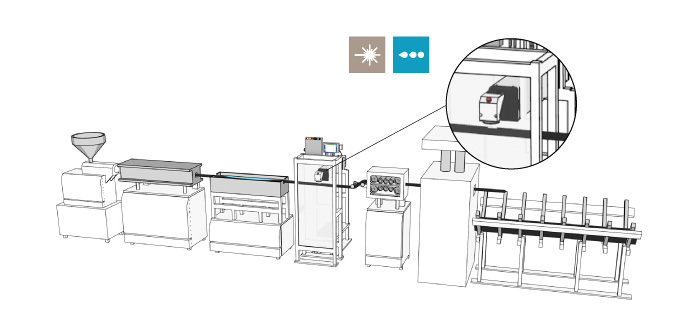

Videojet printers are compatible with continuous operation roto-packers and offer maintenance-minimising features for dusty environments that experience temperature fluctuations. Also, our bulk fluid containers allow the printers to run for longer, reducing the intervals between fluid replacement.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

Ink-based, non-contact printing of multiple data types (alphanumeric, logos and bar codes) in large sizes primarily used for secondary packaging such as cases.

While manufacturing processes of wood products and floor tile vary, they share the challenges of a tough production environment. These products require robust coding solutions that provide crisp, consistent codes with minimised and simplified maintenance for when printers aren’t easily accessible on the line.

Ink-based, non-contact printing using heat and surface tension to move ink onto a package surface. Generally used to print 2D DataMatrix and other bar codes.

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

Ink-based, non-contact printing of multiple data types (alphanumeric, logos and bar codes) in large sizes primarily used for secondary packaging such as cases.

Extrusion facilities are continuous operations and are challenged by hot and dusty conditions. Videojet printers are designed to meet these challenging demands and help keep your lines running.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

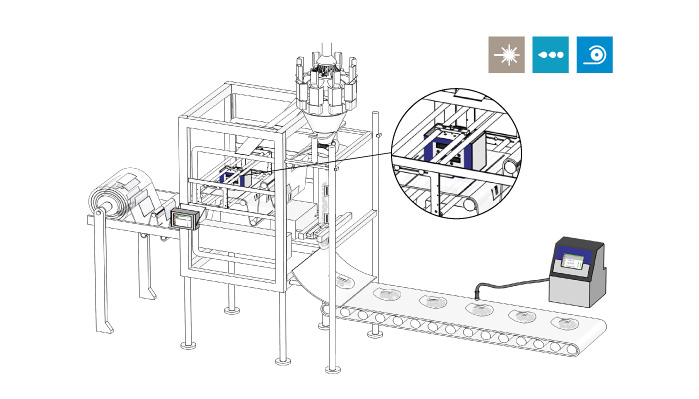

Videojet printers are capable of printing variable information including, but not limited to, logos, product names, and bar codes directly onto flexible film. Thermal Transfer Overprinting (TTO) enables you to use generic standard film (vs. pre-printed films) with product-specific content printed on-demand.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

Thermal Transfer Overprinting (TTO)

A digitally controlled printhead precisely melts ink from a ribbon directly onto flexible films to provide high resolution, real-time prints..