Flexible film coding: a guide to choosing the right technology for improved product safety and compliance in 2026

Videojet Knowledge Hub Team

flexible film coding, mono-materials, product safety, compliance

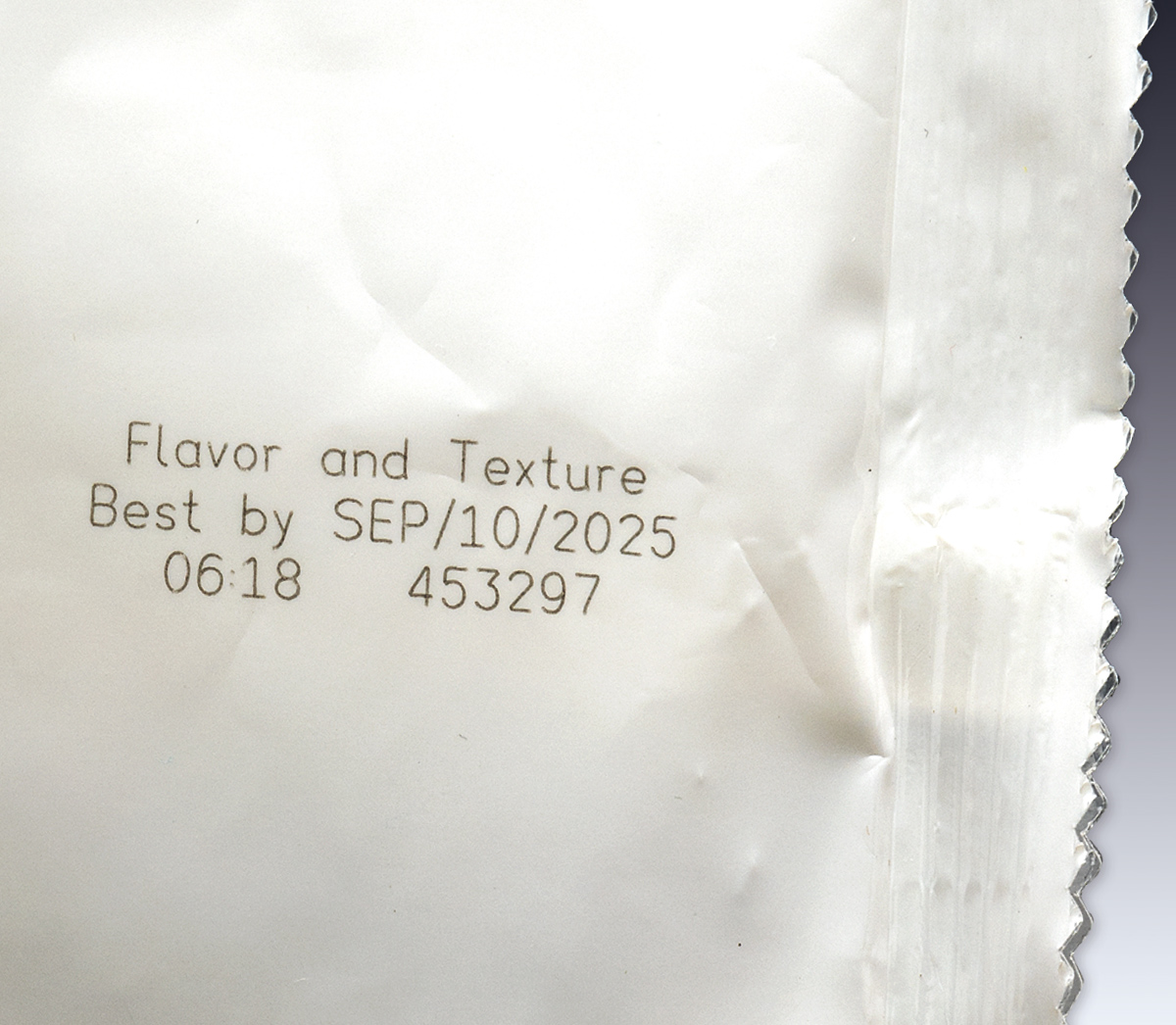

Flexible film coding is the process of printing or marking of variable information, such as dates, batch codes, and traceability data, directly onto flexible packaging materials. Incorrect data poses potential health risks and damage to a company’s reputation. These risks highlight the critical importance of accurate and reliable coding on flexible film packaging to help ensure product safety, compliance, and brand integrity.

Common technologies used for flexible films include laser marking, continuous inkjet (CIJ), thermal inkjet (TIJ), and thermal transfer overprinting (TTO). The appropriate technology is typically selected based on substrate type, production speed, durability requirements, and sustainability considerations.

What is flexible film packaging?

Flexible film refers to a type of packaging made from pliable materials that can easily change shape. These lightweight materials include plastics, like low-density polyethylene (LDPE), Polyethylene Terephthalate (PET), Polypropylene (PP), and flexible metallized films. These materials are widely used for packaging candy and snacks, medical supplies, consumer goods, agricultural products, and industrial products. The flexibility of these films allows for innovative packaging designs that enhance product appeal and functionality.

What are mono-materials?

Mono-materials, made from a single substrate, like PE or PP, to help simplify recycling and promote a circular economy. They help maintain product longevity while reducing waste.

How do mono-materials support sustainability?

Mono-materials are transforming packaging by providing a sustainable alternative to traditional flexible films, which often complicate recycling. Made from a single substrate like PE or PP, they may also have a very thin but high-performance barrier layer for product longevity that doesn’t hinder recyclability of the packaging. Designed to fit into existing recycling systems, they promote a circular economy and can reduce waste. By educating consumers on proper disposal, mono-materials can contribute to the advancement of a circular economy.

What are the advantages of flexible film packaging?

- Cost-effective: Flexible film is much lighter than rigid packaging, helping to reduce transportation costs and environmental impact.

- Durability: Flexible films provide excellent protection against moisture, oxygen, and other contaminants, preserving product quality.

- Versatility: Flexible films can be used to package a wide range of products, from food and beverages to pharmaceuticals and electronics.

- Customizability: Flexible films can enhance product perception. Innovative and functional designs stand out on retail shelves, engaging customers with eye-catching visual appeal.

How do you choose the right marking technology for flexible films?

Selecting the best coding solution depends on your production speed, substrate type, and sustainability goals. Each technology offers unique benefits that can help manufacturers deliver accurate, durable codes and ensure compliance. Explore the right solution to optimize your operations and meet your goals seamlessly.

What are the benefits of advanced laser marking solutions?

Laser systems deliver permanent codes without ink, helping to reduce waste while improving efficiency. UV and fiber lasers are best suited for high-resolution marks and fast speeds. Advances in both laser technologies and film composition make lasers an excellent choice for marking date, lot code, barcodes, 2D codes, and allergen information.

- UV lasers induce color changes on UV-reactive films for permanent, high-resolution coding.

- Systems like the Videojet 7920 incorporate innovative technology to significantly reduce setup times. Its SmartFocus™ feature streamlines the process by automatically adjusting the focus distance to a distance predetermined during setup, accommodating different product sizes and substrates quickly and accurately.

- Fiber lasers are ideal for high-contrast coding at ultra-fast speeds and getting crisp permanent marks on flexible film and foil.

These ink-free solutions can help reduce operational waste, offering advantages to both business and the environment.

“By investing in a state-of-the-art Videojet laser system with Smart Focus, we increased efficiency, minimized set-up times, and improved quality assurance.”

Why use continuous Inkjet (CIJ) coding systems?

- Versatile and designed for high-speed operations

- Can apply codes before or after the film is formed and packaged

- High-quality printing: durable and clear codes

- Best suited for various film types

- Helps ensure the film remains undamaged

How does thermal inkjet (TIJ) deliver high-quality printing?

Thermal inkjet (TIJ) technology is best suited for high-speed precision and exceptional print quality on flexible films. TIJ printers integrate seamlessly into various packaging lines and even offer superior adhesion to non-porous materials like foils and laminated films. With low maintenance costs and cost-effective consumables, TIJ technology is becoming a preferred choice for manufacturers aiming to improve efficiency and sustainability in their packaging processes.

How can thermal transfer printing (TTO) improve efficiency?

Thermal transfer overprinting involves transferring ink from a ribbon onto the substrate using heat. With a selection of ribbon colors for added contrast, TTO printers are best suited for delivering high resolution, variable data printing on a variety of films. TTO codes are known for their durability and resistance to smudging, making TTO ideal for applications that need to withstand harsh conditions. The printers can be seamlessly integrated into packaging equipment like vertical form-fill-seal machines.

How do you prevent poor coding on flexible film with Videojet iAssure™ technology?

Videojet iAssure™ technology, a built-in code quality checker on select Videojet TTO solutions, helps reduce waste and rework with no additional hardware, installation or training. It works by automatically monitoring the print quality and making real-time adjustments to maintain accuracy.

For brands and manufacturers, the benefits of Videojet iAssure include:

- Reduced waste: By minimizing print defects, iAssure helps reduce the amount of wasted material, leading to cost savings.

- Increased efficiency: The automatic adjustments made by Videojet iAssure mean less manual intervention is needed, allowing operators to focus on other tasks.

- Consistent quality: Videojet iAssure helps ensure that each print is of high quality, crucial for maintaining brand integrity and customer satisfaction.

Technology comparison chart for flexible film coding

| Technology | Key features | Advantages | Best suited for |

|---|---|---|---|

| Laser marking (UV & fiber) | Ink-free, permanent coding; SmartFocus™ technology supports quick changeover and setup times | High precision and clarity; durable marks; reduces waste | High-speed lines; permanent marking of dates, lot and batch numbers, barcodes, 2D codes |

| Continuous inkjet (CIJ) | Non-contact printing; applies codes before or after forming | Versatile; high-quality printing; works on various substrates | Large and small production runs; dates, lot and batch codes; flexible integration |

| Thermal inkjet (TIJ) | High-speed precision; superior adhesion on non-porous materials | Exceptional print quality; low maintenance; cost-effective | Packaging lines needing fine detail; date, lot, and batch codes; barcodes and 2D codes; foils and laminated films |

| Thermal Transfer Overprinting (TTO) | Heat transfers ink from ribbon; multiple ribbon colors | Durable, smudge-resistant; high-resolution variable data | Harsh conditions; date, lot, and batch codes, ingredients, barcodes, and 2D codes; vertical form-fill-seal machines |

| Videojet iAssure™ for TTO | Built-in code quality monitoring; real-time adjustments | Helps reduce waste and increase efficiency; helps ensure consistent quality | Brands prioritizing quality assurance and waste reduction |

In general, laser marking offers permanent, ink-free codes for high-speed lines, while CIJ provides versatility across a wide range of flexible films. TIJ excels where high-resolution print quality is required, and TTO is well suited for demanding environments and form-fill-seal applications.

Conclusion

By printing accurate and durable codes and other information, manufacturers can help safeguard consumer health, maintain their reputation, and avoid costly recalls. Selecting the appropriate coding technology whether laser marking, CIJ, TIJ, or TTO based on application requirements and operating conditions can help improve reliability, compliance, and traceability across flexible film packaging lines.